Understanding Unique Device Identification Compliance

23 Sep 2025

UDI Implementation Made Clear for Medical Device Manufacturers

Unique Device Identification (UDI) plays a critical role in medical device regulation worldwide. This system enhances device traceability, improves patient safety, and facilitates regulatory oversight. Medical device manufacturers need a thorough understanding of UDI requirements to ensure ongoing compliance and successful market access.

What is UDI and Why is it Important?

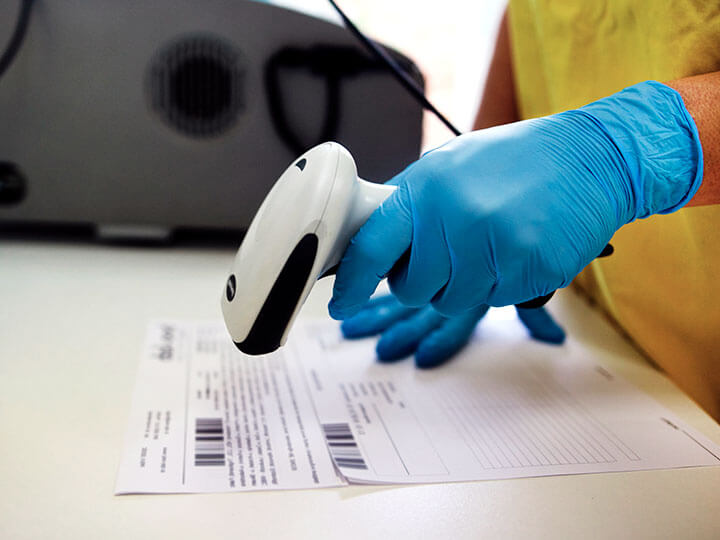

The UDI is a mandatory labeling applied to medical devices and their packaging. It consists of two key forms: a human-readable alphanumeric code and a machine-readable format such as a barcode or RFID. Both forms are required on every level of device packaging and directly on the device itself.

The UDI comprises two parts:

- Device Identifier (DI): A unique code specifying the manufacturer, device model, packaging configuration, and certain device attributes.

- Production Identifier (PI): Includes production-specific data such as manufacturing date, serial number, lot number, or expiration date.

Introduced by the U.S. Food and Drug Administration (FDA) in 2002, the UDI system aims to reduce medical errors, streamline integration with electronic data systems, enable rapid identification during recalls or adverse events, and facilitate efficient communication between manufacturers, regulators, and the public.

Global Regulatory Frameworks Governing UDI

UDI requirements are mandated by major regulatory agencies globally. In the United States, regulations are codified under Title 21 CFR Part 801.20, enforced by the FDA. In the European Union, UDI is governed by the Medical Device Regulation (MDR) Article 27 and In Vitro Diagnostic Regulation (IVDR) Article 24. Manufacturers must register their UDIs in centralized databases: the FDA’s Global Unique Device Identification Database (GUDID) for the U.S., and the European Database on Medical Devices (EUDAMED) for the EU. These databases serve as public resources for device information and support regulatory oversight.

Other countries, including Brazil, China, Australia, Saudi Arabia, and South Korea, are also developing or implementing UDI systems, often harmonizing with US and EU standards through international collaboration platforms like the International Medical Device Regulators Forum (IMDRF).

Key Steps to UDI Implementation for Manufacturers

Implementing UDI involves several crucial steps:

- Understanding Regulatory Requirements: Manufacturers must familiarize themselves with applicable UDI regulations for each target market, including any national deviations or device classification nuances.

- Obtaining the Device Identifier: This is issued by FDA-recognized issuing agencies in the U.S., and corresponding bodies in other regions. Manufacturers create accounts with these agencies and submit detailed device attributes to generate the unique device identifier.

- Determining the Marking Method: UDI markings must appear both in human-readable and machine-readable formats on the device and packaging. For devices subject to reprocessing, permanent direct marking methods such as laser etching or engraving are necessary to ensure durability.

- Registering the UDI: Prior to market release, the device identifier is registered in regulatory databases (GUDID, EUDAMED).

- Ongoing Compliance: UDI is an ongoing responsibility. Manufacturers must continuously update registrations, manage new product variants, and maintain compliance with evolving regulations and technological advances.

Important Reminders on UDI Deadlines and Ongoing Compliance

Although initial deadlines for UDI compliance have passed, regulations continue to evolve and deadlines for newer regulations or additional device classes may still apply. Staying informed is essential. Monitoring updates from industry associations and consulting experts also supports proactive compliance management and risk mitigation.

Manufacturers are encouraged to regularly consult authoritative sources including:

- The FDA’s UDI System website for updated guidance, registration tools, and FAQs.

- The European Commission’s Medical Device Regulations portal for updates on EUDAMED and MDR/IVDR UDI requirements.

- The IMDRF for global harmonization efforts and best practices.

Understanding UDI Variability and Standards

UDI codes vary by product based on device attributes, packaging, and production information. The EU employs a concept called “Basic UDI-DI” to represent product families, while individual device identifiers distinguish specific products and configurations. Manufacturers must also adhere to standards governing UDI legibility, print quality, and barcode verification, such as ISO/IEC 15415, ISO/IEC 15416, and TR 29158. Attention to these standards ensures accurate scanning and data capture, which is critical for supply chain management, patient safety, and regulatory reporting.

The Manufacturer’s Ongoing Role in UDI Compliance

Compliance with UDI regulations is a continuous process requiring vigilance and resource commitment. Even when utilizing third-party issuing agencies or service providers, manufacturers retain ultimate responsibility for:

- Maintaining accurate and up-to-date UDI records.

- Managing device variations and updates.

- Ensuring all marketed devices are correctly labeled and registered.

- Keeping abreast of regulatory changes and technology innovations.

By embracing UDI compliance as an integral part of quality management systems, manufacturers enhance traceability, improve market confidence, and contribute to safer patient outcomes globally.